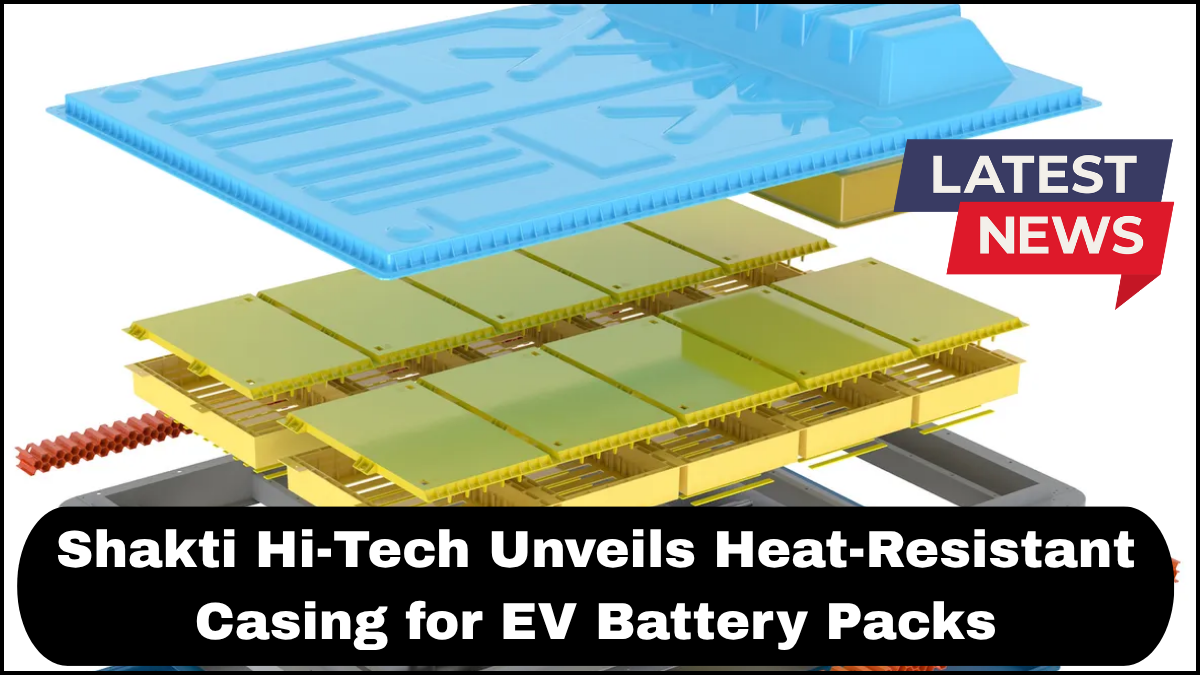

In a significant advancement for electric vehicle (EV) technology, Shakti Hi-Tech, a leading innovator in automotive components, has introduced a new line of heat-resistant casing for EV battery packs. Engineered using advanced materials and cutting-edge manufacturing processes, the new product aims to set a new benchmark in EV battery casing materials, focusing on thermal management, durability, and safety.

A Strategic Leap in EV Battery Protection

With the global EV market expanding at an exponential rate, battery safety has become a critical concern. Incidents involving thermal runaway and overheating have prompted manufacturers to look for battery casing solutions that not only protect internal components but also withstand extreme operating conditions.

Shakti Hi-Tech’s newly unveiled heat-resistant casing system directly addresses these issues. It is designed to contain and isolate thermal events, significantly reducing the risk of fire and extending the operational life of battery packs.

What Sets This Casing Apart?

The standout feature of this innovation lies in the use of heat-resistant composites auto manufacturers are demanding more of. These composites offer superior thermal insulation, mechanical strength, and flame retardancy—essential qualities for battery housings operating in high-stress environments.

The casing incorporates a multi-layer structure made from:

-

High-performance polymers reinforced with ceramic fibers, which remain stable at temperatures exceeding 300°C.

-

Flame-retardant additives, which delay ignition and slow heat transfer.

-

Lightweight structural reinforcements, ensuring the casing remains both protective and efficient without adding unnecessary mass.

By integrating these technologies, Shakti Hi-Tech’s solution strikes a balance between thermal protection and lightweight design, both of which are vital for optimizing vehicle performance and range.

Compliance with Global Safety Standards

The new EV battery casing materials have been tested in accordance with international automotive safety standards, including UL 94 V-0 for flame resistance and ISO 26262 for functional safety. Shakti Hi-Tech also conducted in-house validation tests simulating thermal shock, vibration, and impact to ensure the casing holds up under real-world conditions.

This compliance not only boosts manufacturer confidence but also aligns with the growing regulatory demands around EV battery safety, especially in markets like the European Union, North America, and East Asia.

Implications for the Auto Industry

This launch comes at a pivotal time for the auto industry. As OEMs (Original Equipment Manufacturers) race to electrify their fleets, they are under pressure to deliver vehicles that are not only high-performing but also safe, reliable, and cost-effective. Advanced EV battery casing materials like those from Shakti Hi-Tech can be a game-changer in this regard.

Moreover, the casing’s modular design allows for easier integration across various battery formats and vehicle platforms—reducing development time and customization costs for automakers.

Sustainability in Focus

Shakti Hi-Tech has also emphasized the sustainability of its composite materials. The casings are recyclable and manufactured with reduced energy consumption, aligning with broader green manufacturing goals. This adds another layer of appeal for manufacturers focused on reducing the carbon footprint of their EV supply chain.

Frequently Asked Questions (FAQs)

Q1: Why is heat resistance important in EV battery casings?

A: Heat resistance is critical to prevent thermal runaway, protect sensitive battery cells, and ensure safety in high-temperature conditions. Without proper thermal insulation, batteries can overheat, leading to fire hazards or system failure.

Q2: What are heat-resistant composites in automotive applications?

A: These are engineered materials made by combining polymers with reinforcing elements like glass or ceramic fibers. They offer high thermal stability, structural strength, and resistance to flames, making them ideal for automotive and battery protection.

Q3: How do Shakti Hi-Tech’s casings differ from traditional metal housings?

A: Unlike traditional aluminum or steel casings, Shakti’s composite casings are significantly lighter and offer better thermal insulation. They reduce heat conduction and are more adaptable for custom battery designs.

Q4: Are these casings compatible with all types of EVs?

A: Yes, the modular design allows Shakti Hi-Tech’s casings to be configured for a wide range of EV battery architectures, from compact city cars to heavy-duty electric trucks.

Q5: Do these casings contribute to overall vehicle efficiency?

A: Absolutely. Their lightweight nature reduces vehicle mass, which in turn improves battery efficiency and extends driving range.

click here to learn more