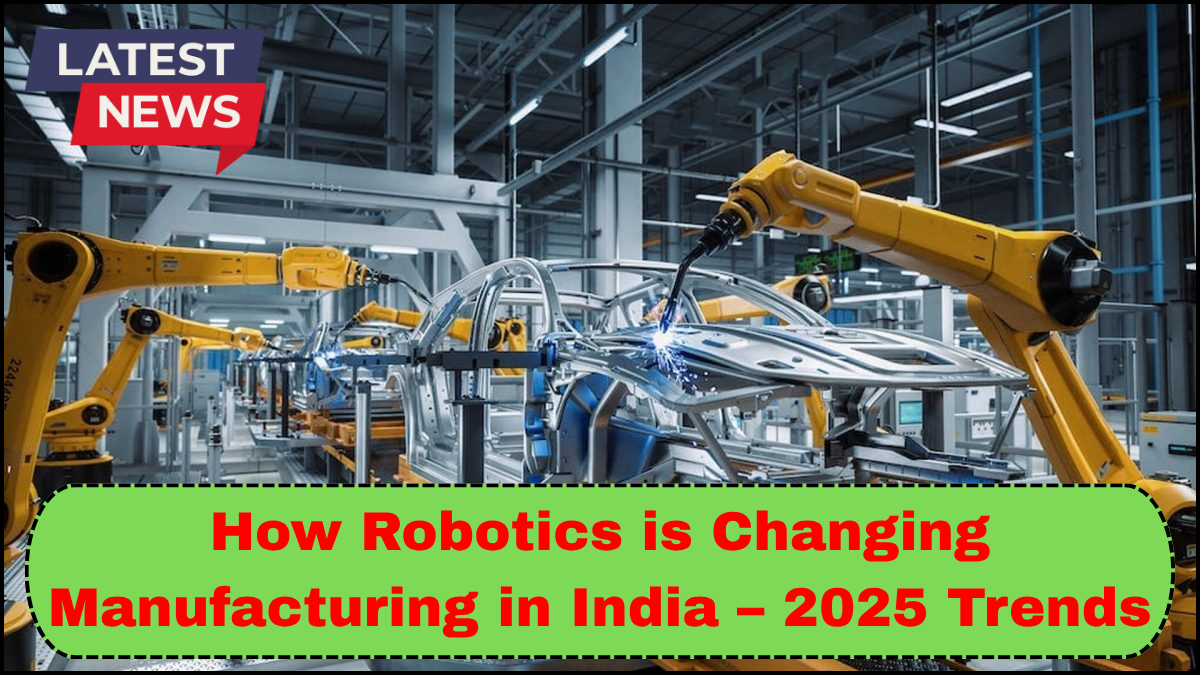

India’s manufacturing sector is undergoing a seismic shift. At the center of this transformation is robotics. As the global race toward smart factories accelerates, robotics in manufacturing in India is no longer a futuristic idea—it’s the present reality. In 2025, we’re witnessing automation take the wheel in ways that are redefining production lines, labor dynamics, and industry efficiency.

Rise of Smart Factories

Manufacturing units across India are embracing smart factory concepts, integrating robots with AI, IoT, and data analytics. These next-gen setups go far beyond traditional automation. Robots now handle complex tasks—assembly, welding, packaging, inspection—with precision and consistency.

Industries such as automotive, electronics, pharmaceuticals, and textiles are leading the way. For instance, Tata Motors and Mahindra have introduced robotic arms in their vehicle assembly lines to improve speed and accuracy while reducing human error.

Labor Efficiency, Not Replacement

A common concern is that robots might displace human workers. The reality in India tells a different story. Instead of replacing jobs, robotics in manufacturing in India is augmenting human capabilities. Cobots (collaborative robots) are working alongside workers, handling repetitive or hazardous tasks, allowing humans to focus on problem-solving and oversight.

This shift also demands a new wave of skill development. Companies are investing in training programs to upskill employees in robotics programming, maintenance, and system integration.

Automation as a Competitive Advantage

India’s push for “Make in India” and becoming a global manufacturing hub depends heavily on adopting advanced automation. In 2025, automation 2025 trends indicate a strong move toward flexible manufacturing systems—robotic setups that can quickly switch between product types with minimal downtime.

This agility is crucial for Indian exporters dealing with volatile international demand and tight turnaround times. Robotics is helping companies maintain quality while scaling operations quickly and cost-effectively.

Affordable Robotics: Breaking the Barrier

One of the major 2025 trends is the rise of affordable robotics solutions tailored for small and medium enterprises (SMEs). Startups and tech providers are offering modular robotic kits and leasing options that lower the entry cost significantly. Companies like Systemantics and Asimov Robotics are developing Indian-made robots that are cost-effective and customized for local industries.

This democratization of robotics is accelerating adoption beyond large corporations and into tier-2 and tier-3 industrial belts.

Predictive Maintenance & AI Integration

Modern robots in Indian factories are no longer isolated machines. They’re connected systems, feeding real-time data to central dashboards. Predictive maintenance is emerging as a game-changer. With AI-driven insights, companies can anticipate equipment failure before it happens, reducing downtime and extending the life of machinery.

This AI-robotics integration is especially useful in sectors like food processing and electronics, where downtime can lead to massive revenue losses.

Government Push & Policy Support

Government initiatives are reinforcing this momentum. Schemes like the Production-Linked Incentive (PLI), the National Policy on Advanced Manufacturing, and partnerships with global automation leaders are fueling investment in robotics.

The Ministry of Heavy Industries is also supporting research and development in robotics and automation, signaling long-term commitment.

Sustainability Through Robotics

Sustainability is now a key concern for manufacturers. Robotics is contributing by optimizing energy usage, reducing material waste, and supporting eco-friendly practices. Automated systems are more precise, ensuring minimal wastage in processes such as material cutting, painting, and packaging.

Robotics is also being used in recycling and e-waste management, particularly in electronics manufacturing.

Frequently Asked Questions (FAQ)

Q1: What industries in India are using robotics the most in 2025?

A1: Automotive, electronics, pharmaceuticals, food processing, and textiles are among the top industries adopting robotics in India.

Q2: Are robots replacing human jobs in Indian manufacturing?

A2: No. In most cases, robots are being used to support human workers, not replace them. Cobots are working alongside humans to improve efficiency and safety.

Q3: What is driving the growth of robotics in manufacturing in India?

A3: Factors include government policies, demand for higher efficiency, cost savings, quality control, and the need to stay competitive in global markets.

Q4: Can small businesses in India afford robotics?

A4: Yes. With modular and affordable robotic solutions now available, even small and mid-sized manufacturers can implement automation.

Q5: How is robotics supporting sustainability in manufacturing?

A5: Robotics enhances precision, reduces waste, optimizes energy usage, and enables eco-friendly production processes.

cliock here to learn more