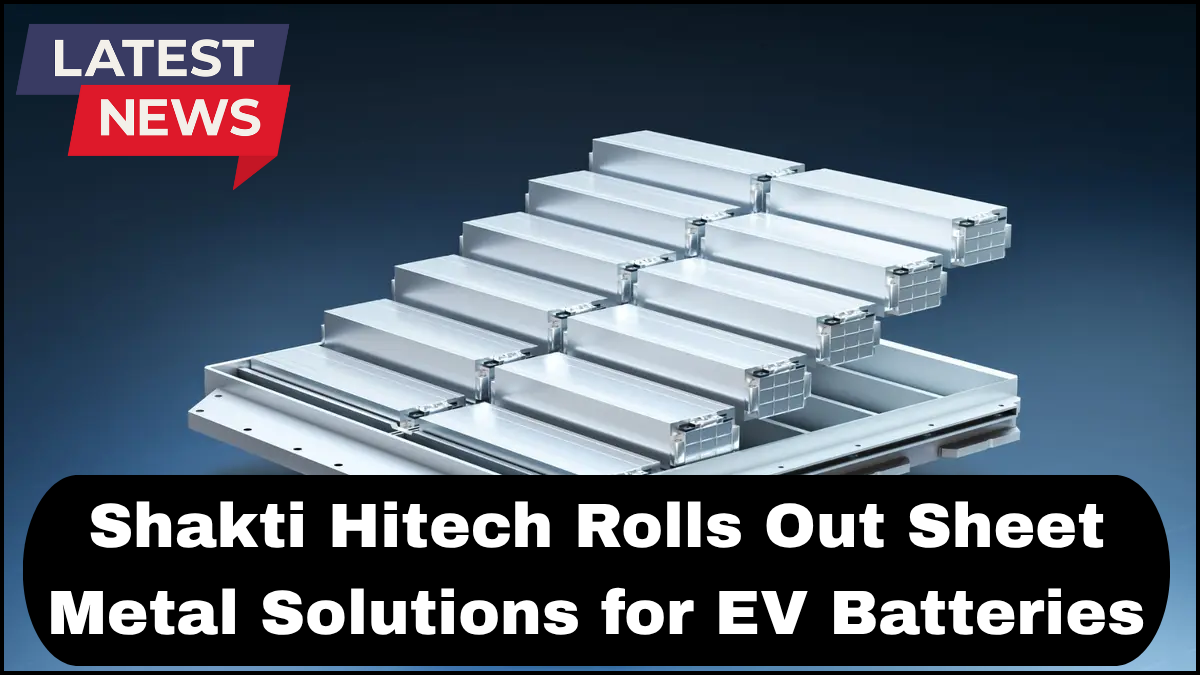

Shakti Hitech, a leading player in precision manufacturing, has launched a new line of sheet metal solutions for EV batteries, signaling a major step forward in India’s clean mobility manufacturing sector. This move aligns with the growing demand for electric vehicles and addresses the urgent need for reliable, scalable, and thermally efficient enclosures and components for EV battery systems.

As the EV industry continues to evolve at a rapid pace, the need for high-performance sheet metal components has become more critical than ever. Shakti Hitech’s new offering aims to bridge the performance, durability, and cost-efficiency gap in battery housing and thermal control systems.

Addressing the Core Challenge in EV Battery Design

Electric vehicle batteries are the heart of any EV. Their structure must meet high safety standards, thermal management efficiency, and protection from physical damage, all while being lightweight to support vehicle performance.

Shakti Hitech’s sheet metal solutions target these requirements with precision-engineered housings, brackets, cooling plates, and structural frames designed specifically for lithium-ion battery packs. These components are manufactured using high-grade aluminum and steel alloys, ensuring optimal strength-to-weight ratios.

Additionally, the company integrates smart design principles to accommodate battery swelling, electromagnetic interference (EMI) shielding, and efficient airflow—all vital factors for long-term battery performance and passenger safety.

Cutting-Edge Industrial Metal Cutting Technology

One of Shakti Hitech’s key differentiators lies in its adoption of advanced industrial metal cutting techniques. The firm utilizes CNC laser cutting, high-speed stamping, and robotic welding systems to deliver consistently precise components.

This automated, high-precision environment ensures minimal material waste, faster turnaround times, and superior surface finishes—all of which are crucial for maintaining consistency across high-volume production runs of EV battery packs.

Moreover, the integration of real-time quality monitoring and AI-driven inspection tools reinforces Shakti Hitech’s commitment to zero-defect manufacturing. This is especially important in EV battery production, where even minor defects in sheet metal components can lead to significant safety and performance issues.

Customization and Scalability: Meeting OEM Demands

Shakti Hitech isn’t just producing off-the-shelf solutions; it’s offering tailored components that cater to the unique configurations of different electric vehicle manufacturers. Their engineering team works closely with OEMs to co-develop parts that fit specific dimensional, thermal, and mechanical needs.

From compact urban EVs to high-capacity electric trucks, the company’s scalable production setup supports a broad range of vehicle types. This flexibility gives OEMs a reliable partner as they transition their fleets toward full electrification.

Sustainable Manufacturing Practices

Environmental sustainability is at the core of Shakti Hitech’s new venture. The facility utilizes eco-friendly coatings, recycles scrap metal, and follows energy-efficient production protocols. This aligns with the broader sustainability goals of EV manufacturers and regulatory bodies focused on reducing the automotive industry’s carbon footprint.

By focusing on sheet metal for EV batteries that are not only functional but environmentally responsible, Shakti Hitech positions itself as a forward-thinking partner in the clean mobility revolution.

India’s EV Supply Chain Gets a Boost

India’s push for electric vehicles under initiatives like FAME II and PLI schemes has triggered a growing need for a localized, high-quality supply chain. Shakti Hitech’s entry into the battery component segment strengthens the domestic ecosystem, reducing dependency on imports and improving lead times for Indian EV manufacturers.

With its state-of-the-art facilities and a track record of delivering precision-engineered products across industries, Shakti Hitech is well-positioned to become a key enabler in India’s EV transformation.

Frequently Asked Questions (FAQs)

Q1: What makes sheet metal important for EV batteries?

A: Sheet metal is critical in protecting EV battery packs, supporting thermal regulation, and ensuring structural stability. It also plays a key role in housing electronic and cooling systems within the battery architecture.

Q2: What materials are typically used in sheet metal components for EV batteries?

A: Lightweight and corrosion-resistant materials like aluminum and specific grades of steel are commonly used to balance strength, weight, and heat dissipation needs.

Q3: How does industrial metal cutting impact EV battery production?

A: Precision industrial metal cutting ensures tight tolerances, repeatability, and clean finishes, which are essential for the safety and efficiency of EV battery components.

Q4: Is Shakti Hitech providing custom solutions or standard parts?

A: Shakti Hitech specializes in both standard and fully customized sheet metal components tailored to specific OEM and battery design requirements.

Q5: How does Shakti Hitech ensure product quality in high-volume manufacturing?

A: The company uses automation, AI-powered inspection tools, and stringent quality control protocols to ensure defect-free production across every batch.

click here to learn more