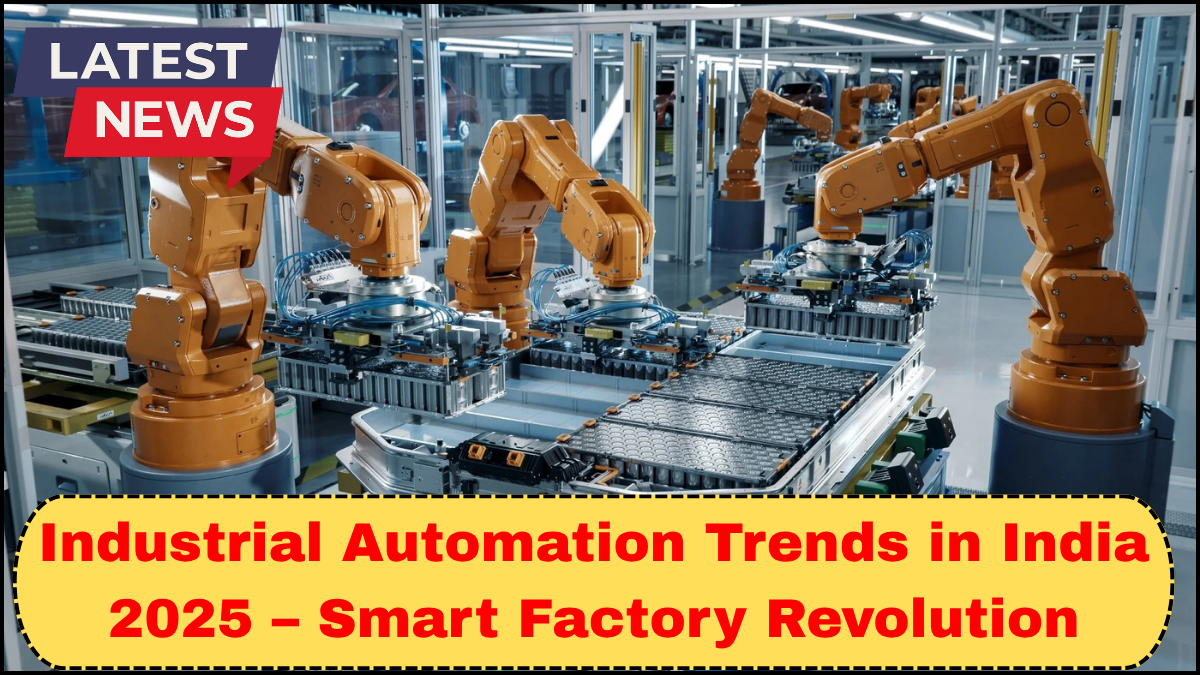

India is witnessing a seismic shift in how industries operate. As 2025 approaches, the rise of smart technologies is redefining traditional manufacturing and laying the groundwork for the next generation of production. The Industrial Automation Trends in India 2025 point toward a transformative era—where machines are intelligent, factories are connected, and operations are data-driven.

From predictive maintenance to AI-powered robotics, India’s industrial ecosystem is not just catching up with global standards—it’s aiming to lead. Here’s a deep dive into the top trends shaping this smart factory revolution.

Surge in Smart Factory Adoption Across Sectors

Smart factory adoption is no longer limited to large multinationals. In India, medium and even small-scale enterprises are beginning to embrace automated systems that improve efficiency, reduce errors, and scale faster. This includes everything from programmable logic controllers (PLCs) and Internet of Things (IoT) devices to real-time data dashboards and cloud integration.

Sectors like automotive, pharmaceuticals, electronics, and FMCG are especially aggressive in shifting to smart factory models. The drive is fueled by the need for precision, speed, compliance, and traceability.

AI and Machine Learning Powering Intelligent Decision-Making

Artificial Intelligence (AI) and Machine Learning (ML) are becoming the brains behind industrial automation. In 2025, factories will use these technologies not just for automation, but for optimization.

AI algorithms analyze data from thousands of sensors to make real-time decisions—predicting equipment failures, improving supply chain logistics, and fine-tuning production processes. For instance, Tata Steel’s use of ML for blast furnace control has shown measurable improvements in productivity and resource use.

Edge Computing Taking Over Traditional Cloud Models

Cloud computing was a game-changer, but Industrial Automation Trends in India 2025 highlight the rapid rise of edge computing. Processing data closer to the source (i.e., on-site machines and sensors) reduces latency, enhances security, and enables faster decision-making.

This is especially useful in high-speed production environments where milliseconds matter. Edge devices are now being embedded with AI capabilities, enabling smarter responses without relying entirely on centralized systems.

Digital Twins Reshaping Industrial Planning and Testing

A digital twin is a virtual replica of a physical asset, process, or system. In India, this technology is now being deployed for simulation, diagnostics, and optimization of manufacturing operations.

Companies like L&T and Bharat Forge are leveraging digital twins to simulate real-world manufacturing scenarios, identify potential bottlenecks, and test system performance before actual implementation. This not only saves cost but drastically reduces downtime and risk.

Human-Machine Collaboration: Not Just Automation, But Augmentation

Contrary to the fear that automation replaces human jobs, the new wave emphasizes human-machine collaboration. Cobots (collaborative robots) are designed to work safely alongside human workers, handling repetitive tasks while humans focus on problem-solving and innovation.

Smart factory adoption also includes upskilling initiatives, where the workforce is trained to operate, monitor, and optimize automated systems, ensuring that the shift benefits both productivity and employment.

Cybersecurity and Data Integrity Become Critical

As factories become more connected, the risk of cyberattacks increases. In 2025, cybersecurity isn’t an afterthought—it’s a core part of automation strategies. Indian manufacturers are investing heavily in secure architectures, encrypted communication, and access controls to protect their data assets and maintain regulatory compliance.

Government initiatives like the National Cyber Security Strategy and data localization norms further underline the importance of secure digital infrastructure in industrial automation.

Sustainability Through Automation and Smart Energy Use

One of the lesser-talked-about but vital Industrial Automation Trends in India 2025 is sustainability. Smart factories aim not only for efficiency but also for environmental responsibility.

Automation systems now include energy monitoring tools, waste reduction protocols, and carbon footprint analytics. Companies are using this data to reduce emissions, optimize energy usage, and meet ESG goals—all while improving bottom-line performance.

Government Push and Policy Support

The Indian government’s push through initiatives like “Make in India,” “Digital India,” and the “PLI Scheme” (Production Linked Incentives) has made industrial automation a strategic priority. Subsidies, tax breaks, and infrastructure support have significantly lowered the entry barrier for companies to adopt smart factory solutions.

Conclusion

India’s journey into smart manufacturing is not a futuristic concept—it’s happening now. The Industrial Automation Trends in India 2025 reflect a broader industrial renaissance powered by smart factory adoption, advanced analytics, edge intelligence, and collaborative robotics. For businesses aiming to stay competitive and resilient, embracing this revolution is no longer optional—it’s essential.

Frequently Asked Questions (FAQ)

Q1. What is the smart factory revolution in India?

The smart factory revolution in India refers to the integration of advanced automation, data analytics, IoT, AI, and edge computing into manufacturing processes. It transforms traditional factories into intelligent, self-optimizing systems.

Q2. Which industries are leading smart factory adoption in India?

Key sectors include automotive, aerospace, electronics, pharmaceuticals, and consumer goods. These industries are investing heavily in automation to improve quality, reduce downtime, and scale operations.

Q3. How is the Indian government supporting industrial automation?

Through initiatives like “Digital India,” “Make in India,” and PLI schemes, the government is providing financial incentives, regulatory support, and digital infrastructure to encourage automation and modernization of manufacturing.

Q4. Will automation reduce jobs in India?

Not necessarily. While some manual roles may be automated, new roles are being created in system monitoring, data analysis, maintenance, and AI-driven process management. The focus is shifting from replacement to augmentation.

Q5. What’s the future outlook for automation in India post-2025?

India is poised to become a global manufacturing hub with smart factories at its core. Continuous innovation, policy support, and a growing skilled workforce will drive automation adoption well beyond 2025.

click here to learn more