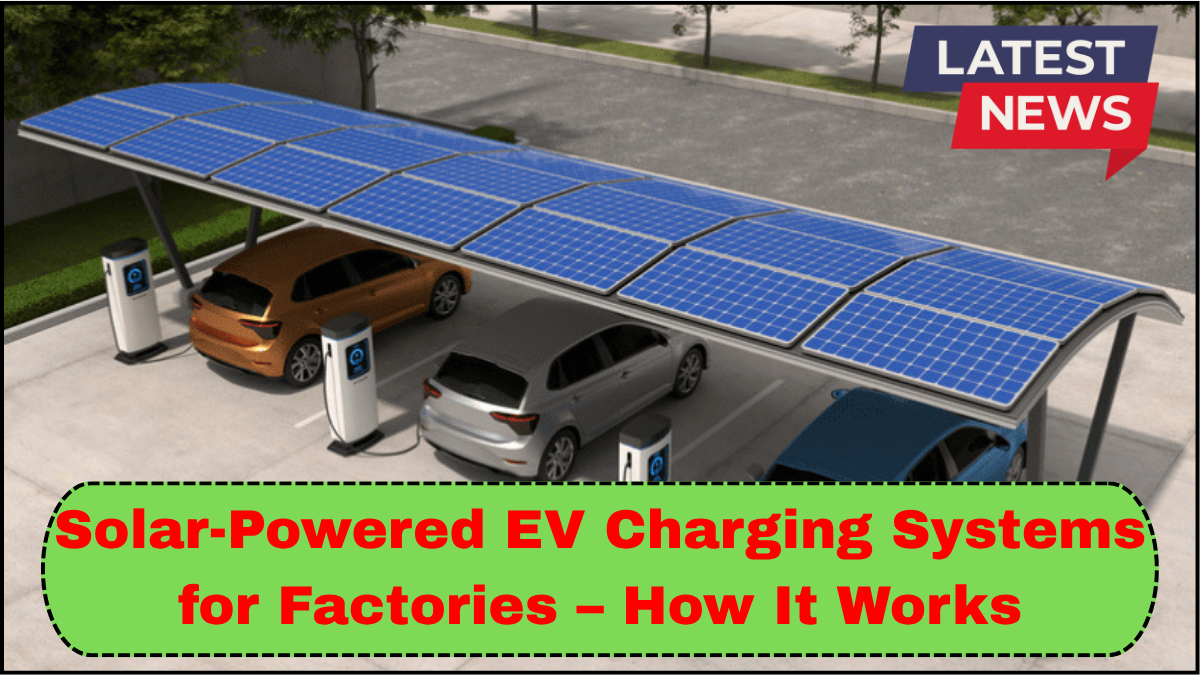

As electric vehicles (EVs) gain traction across the globe, industrial facilities are shifting gears to support the electrification of their operations. One of the smartest moves a factory can make today is integrating solar-powered EV chargers into its infrastructure. This not only reduces operational costs but also supports sustainability goals and energy independence. Here’s a deep dive into how solar-powered EV charging systems function in a factory setting, and why hybrid infrastructure is key to long-term success.

How Do Solar-Powered EV Charging Systems Work?

At the core, a solar-powered EV charging system captures sunlight through photovoltaic (PV) panels, converts it into electrical energy, and stores or supplies this energy directly to electric vehicles. But in a factory setup, things work on a more advanced scale.

-

Solar PV Array Installation

-

Panels are installed on rooftops, carports, or adjacent land spaces.

-

The system size depends on the factory’s energy consumption and the number of EVs needing charging.

-

Industrial-grade PV arrays often produce anywhere from 100 kW to multiple megawatts.

-

-

Inverter Conversion

-

The direct current (DC) generated by solar panels is converted into alternating current (AC) using inverters.

-

These industrial inverters are designed for high loads, allowing multiple EV chargers to operate simultaneously without bottlenecks.

-

-

Energy Management System (EMS)

-

A smart EMS controls when and how much energy goes into charging EVs.

-

It prioritizes solar power and shifts to backup or grid energy only when necessary.

-

Peak shaving, load balancing, and demand response are commonly built into these systems to optimize performance.

-

-

EV Chargers

-

High-speed DC chargers or Level 2 AC chargers are typically installed depending on the types of vehicles used (fleet vans, trucks, employee cars, etc.).

-

Chargers are usually connected to an app or dashboard for real-time usage monitoring and scheduling.

-

Integrating Hybrid Infrastructure for Maximum Efficiency

Relying solely on solar power isn’t always practical—especially in areas with variable weather or high operational demands. That’s where hybrid infra comes into play.

A hybrid infrastructure combines solar energy with grid power and/or battery storage to ensure consistent EV charging availability. Here’s how it works:

-

Grid-Tied Backup: When solar output is low, the system automatically draws power from the grid.

-

Battery Storage: Excess solar energy is stored in large-scale batteries for use during non-peak sunlight hours or power outages.

-

Load Optimization: Smart controls distribute power between solar, grid, and battery sources based on cost-efficiency and availability.

This combination ensures that EV charging remains uninterrupted while maximizing solar utilization.

Key Benefits for Factories

-

Lower Operating Costs: Factories can offset a significant portion of their electricity bills by producing their own charging power.

-

Sustainability Compliance: Reduces carbon emissions and aligns with ESG goals and green certifications.

-

Energy Resilience: In hybrid setups, factories are less vulnerable to grid outages or price spikes.

-

Scalable Solutions: Solar-powered EV charging systems can grow with the factory’s fleet and energy demands.

Real-World Example

An automotive parts factory in Texas installed a 1.2 MW solar system paired with 50 EV chargers and battery storage. The result: a 60% reduction in energy costs, full EV fleet support, and a 10-year ROI. This example highlights the practical and financial sense of adopting solar-powered EV chargers at scale.

Challenges and Considerations

-

Initial Investment: High upfront costs for solar panels, inverters, and charging infrastructure.

-

Space Requirements: Sufficient rooftop or land area is needed for solar panel installation.

-

Maintenance: Although minimal, solar systems and EV chargers require periodic checks and cleaning to maintain efficiency.

These are manageable hurdles when weighed against the long-term benefits.

Frequently Asked Questions

Q1: Can a factory completely disconnect from the grid with solar-powered EV chargers?

A: While technically possible, it’s not practical for most factories due to variability in solar production. A hybrid infra approach provides better reliability.

Q2: What type of EV chargers are ideal for industrial use?

A: High-speed DC fast chargers are preferred for commercial fleets, while Level 2 chargers work well for employee vehicles.

Q3: How long does it take to install a solar-powered EV charging system?

A: Depending on the size, installation can take between a few weeks to several months, including design, permitting, and setup.

Q4: Are government incentives available for installing solar-powered EV charging systems?

A: Yes. Many regions offer tax credits, rebates, and grants to support renewable energy projects in the industrial sector.

click here to learn more